By Sam Barrett, Sustainability Intern

Plastic's story is often one of being thrown away after a single use without a second thought, ending up in a landfill left for thousands of years. Now the story is being rewritten, and it's a tale of innovation, hard-work, and endless possibilities. Tepperman's is on a mission to show that recycling plastic isn't just a solution, but a stepping stone to a thriving circular economy.

1. Embrace Fall Comfort at Home with Cozy Sofas & Sectionals

Plastic's story is often one of being thrown away after a single use without a second thought, ending up in a landfill left for thousands of years. Now the story is being rewritten, and it's a tale of innovation, hard-work, and endless possibilities. Tepperman's is on a mission to show that recycling plastic isn't just a solution, but a stepping stone to a thriving circular economy.

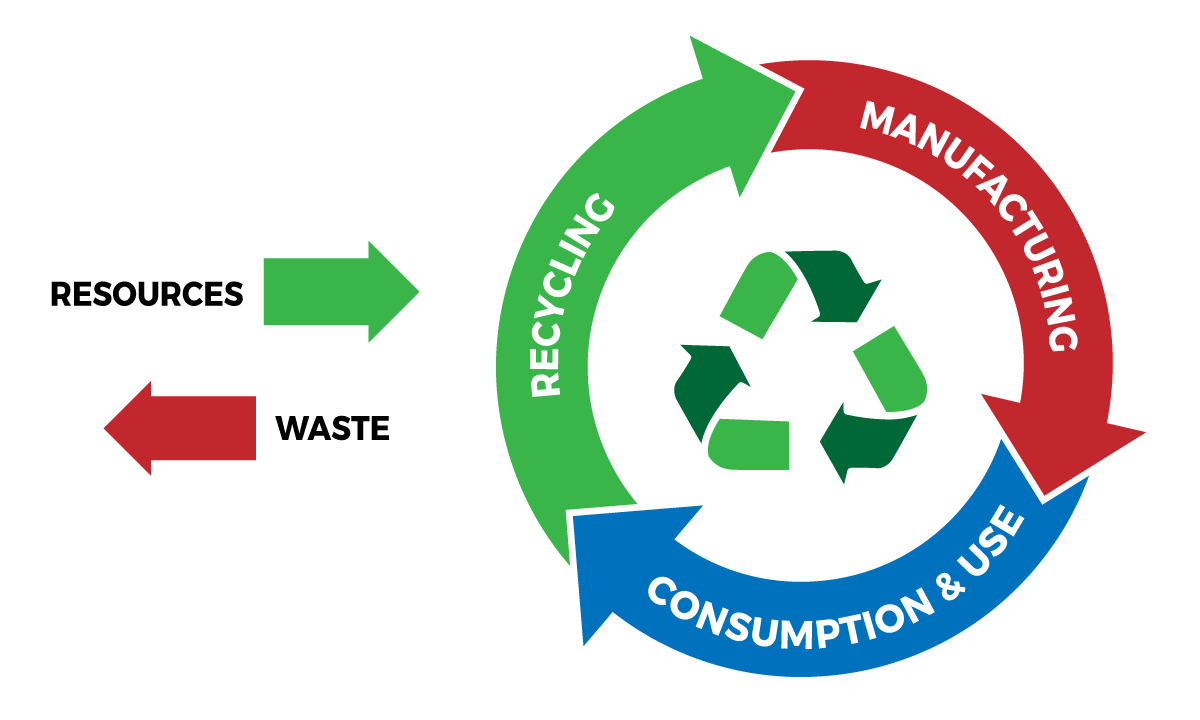

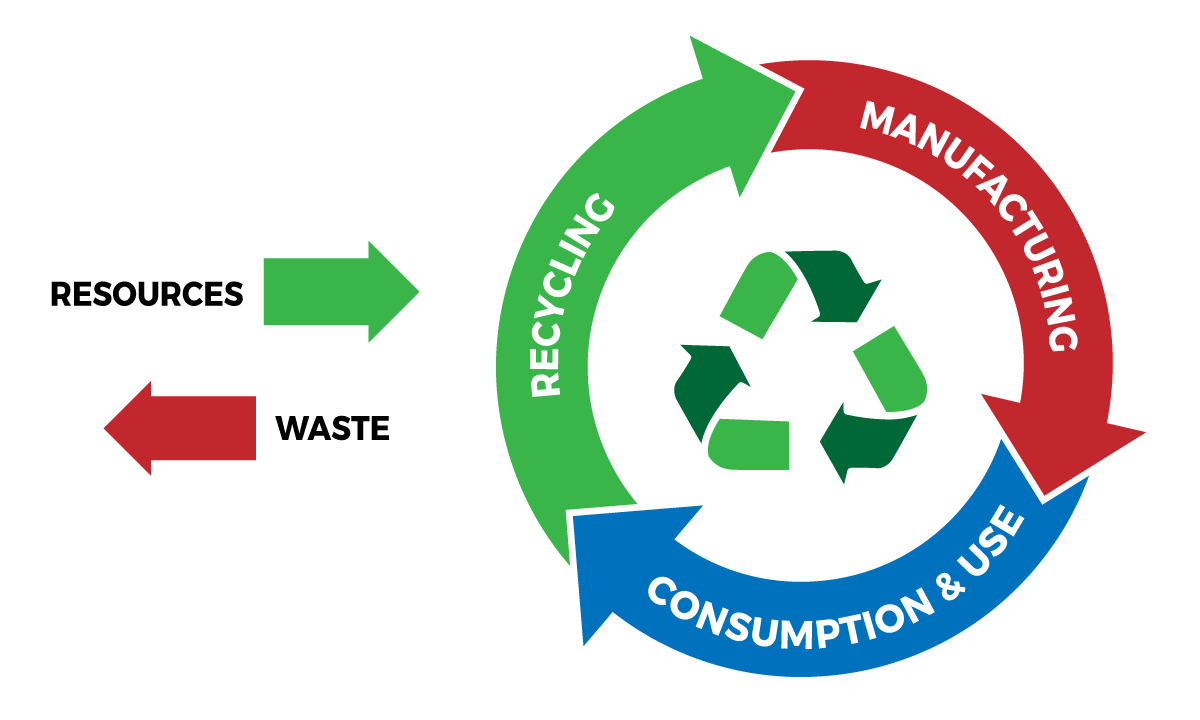

In the traditional "take-make-waste" model of our current economy, plastics have played a major role in our throwaway culture. Single-use items pollute our environment, generating excessive and needless amounts of waste. Enter the circular economy – where plastic waste is viewed as a valuable resource rather than garbage, in an effort to close the loop on production and disposal. Plastics are no longer expendable; they're valuable resources to be repurposed. This new approach ensures plastics are continuously recycled, repurposed, or reused, drastically reducing waste and the environmentally taxing production of new plastic, while lessening our ecological footprint.

1. Embrace Fall Comfort at Home with Cozy Sofas & Sectionals

In the traditional "take-make-waste" model of our current economy, plastics have played a major role in our throwaway culture. Single-use items pollute our environment, generating excessive and needless amounts of waste. Enter the circular economy – where plastic waste is viewed as a valuable resource rather than garbage, in an effort to close the loop on production and disposal. Plastics are no longer expendable; they're valuable resources to be repurposed. This new approach ensures plastics are continuously recycled, repurposed, or reused, drastically reducing waste and the environmentally taxing production of new plastic, while lessening our ecological footprint.

Amongst our many waste diversion efforts, our plastic recycling initiatives in partnership with EFS Plastics directly give plastic a second life as a new product. As Tepperman’s collects all the packaging from our customer drop-offs, we amass many mattress bags, which are composed of low-density polyethylene (LDPE), or plastic film. These bags are sent to the EFS Plastics recycling facility in Listowel, Ontario, where the closed-loop manufacturing process of recycling them into a new product begins.

1. Embrace Fall Comfort at Home with Cozy Sofas & Sectionals

Amongst our many waste diversion efforts, our plastic recycling initiatives in partnership with EFS Plastics directly give plastic a second life as a new product. As Tepperman’s collects all the packaging from our customer drop-offs, we amass many mattress bags, which are composed of low-density polyethylene (LDPE), or plastic film. These bags are sent to the EFS Plastics recycling facility in Listowel, Ontario, where the closed-loop manufacturing process of recycling them into a new product begins.

Once the mattress bags arrive at EFS, they are sorted with other plastic film materials, and any contaminants or debris are removed through cleaning and processing. The plastic film is then shredded into small pieces, which are then heated and extruded. Once this is complete, the extruded LDPE is cooled and cut into small pellets, like you see below. These pellets known as PCR (post-consumer recycled) resin pellets, are the mattress bags given a second life. These pellets have multiple different paths they may follow, such as being sent to the EFS plant in Exeter, where they can be turned into traffic cones, garbage/recycling bins or building material. They can also be sold to a third-party company, which will use the PCR resin pellets to manufacture their products, using recycled materials which in this case, are mattress bags from Tepperman’s.

1. Embrace Fall Comfort at Home with Cozy Sofas & Sectionals

Once the mattress bags arrive at EFS, they are sorted with other plastic film materials, and any contaminants or debris are removed through cleaning and processing. The plastic film is then shredded into small pieces, which are then heated and extruded. Once this is complete, the extruded LDPE is cooled and cut into small pellets, like you see below. These pellets known as PCR (post-consumer recycled) resin pellets, are the mattress bags given a second life. These pellets have multiple different paths they may follow, such as being sent to the EFS plant in Exeter, where they can be turned into traffic cones, garbage/recycling bins or building material. They can also be sold to a third-party company, which will use the PCR resin pellets to manufacture their products, using recycled materials which in this case, are mattress bags from Tepperman’s.

While this closed-loop process is only one of several that Tepperman's undergoes in order to increase our waste diversion, it showcases a realistic and necessary component of transitioning towards a circular economy. Understanding that our planet has finite resources amidst the growing impacts of climate change, we are taking responsibility now to drive change, and hope to pursue even more aspects of the circular economy in the near future.

Click here to learn more about the sustainable business practices at Tepperman’s.